Manual Foam Monitor

Manual Foam Monitor (9)

Back to product categories

Position

Connection

Active Filters:

Clear all

VMH

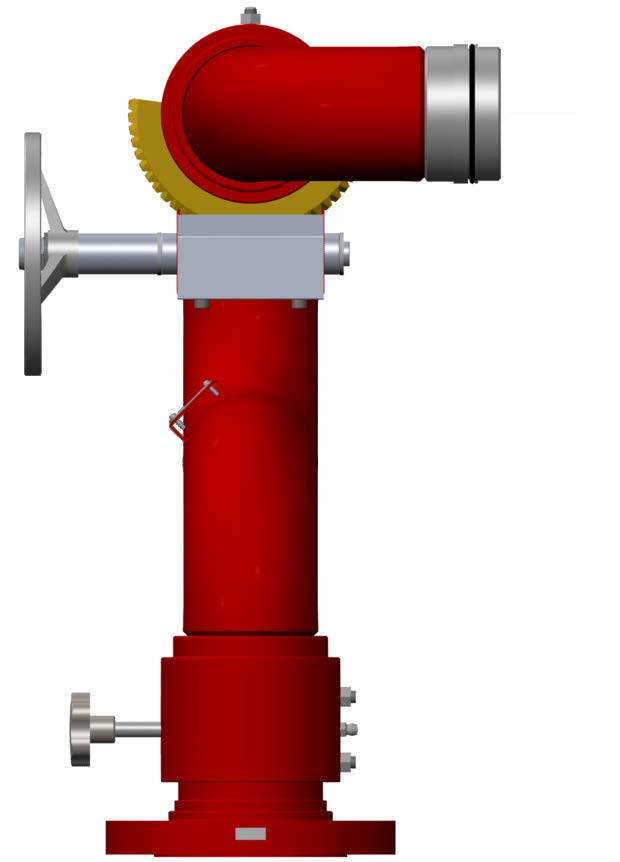

VMH 1-Handwheel Operated Monitor

The “VMH” 1-handwheel operated monitor is available in a 3” body size for 750 and 1,000 GPM flows and comes with 2 swivels. ; This model gives a handwheel control of the vertical movement with a locking knob for the horizontal movement. Whilst the handwheel gives a more controlled functionality at higher pressures, the horizontal movement is limited which means this unit is more suited to use with the oscillating unit. ; ; Monitors are fixed fire suppression discharge devices used in the application of firefighting water or foam solution to a specific area or risk. Monitors are an effective way of covering large areas of application. Manual or oscillating monitors are usually part of a fixed deluge or flow control system but can also be supplied locally via hydrant or fire truck hose supplies. Monitors can also be mounted on mobile trailers for greater versatility in challenging fire scenarios. Monitors are commonly used in high risk areas such as flammable liquid storage tank farms, loading racks, incineration facilities, recycling plants, aircraft hangars, helidecks and jetty protection.

VMH The “VMH” 1-handwheel operated monitor is available in a 3” body size for 750 and 1,000 GPM flows and comes with 2 swivels. ; This model gives a handwheel control of the vertical movement with a locking knob for the horizontal movement. Whilst the handwheel gives a more controlled functionality at higher pressures, the horizontal movement is limited which means this unit is more suited to use with the oscillating unit. ; ; Monitors are fixed fire suppression discharge devices used in the application of firefighting water or foam solution to a specific area or risk. Monitors are an effective way of covering large areas of application. Manual or oscillating monitors are usually part of a fixed deluge or flow control system but can also be supplied locally via hydrant or fire truck hose supplies. Monitors can also be mounted on mobile trailers for greater versatility in challenging fire scenarios. Monitors are commonly used in high risk areas such as flammable liquid storage tank farms, loading racks, incineration facilities, recycling plants, aircraft hangars, helidecks and jetty protection.

Documents & Resources (2)

Download all documents

Download selected files (1)

Add to download box (1)

Foam Systems

Product sheet

Languages

Foam Systems

Data page

Languages

Product Variants

- SAP number VMH3X3A

- Connection Flange

- Connection type ANSI

- Size 3″/DN80

- Size 2 3″ Body

- Finish Flame red RAL3000

- Main material Stainless steel 316 | Flange: Stainless steel

- Style Manual – Handwheel

- Movement 2 Swivel – Vertical, Horizontal

- Maximum working pressure 17,2

- Nominal flowrate 3,785 @ 6.89 bar

- Maximum flowrate 3785

- SAP number VMH3X4A

- Connection Flange

- Connection type ANSI

- Size 4″/DN100

- Size 2 3″ Body

- Finish Flame red RAL3000

- Main material Stainless steel 316 | Flange: Stainless steel

- Style Manual – Handwheel

- Movement 2 Swivel – Vertical, Horizontal

- Maximum working pressure 17,2

- Nominal flowrate 3,785 @ 6.89 bar

- Maximum flowrate 3785

- SAP number VMH3X4P

- Connection Flange

- Connection type PN16

- Size 4″/DN100

- Size 2 3″ Body

- Finish Flame red RAL3000

- Main material Stainless steel 316 | Flange: Stainless steel

- Style Manual – Handwheel

- Movement 2 Swivel – Vertical, Horizontal

- Maximum working pressure 17,2

- Nominal flowrate 3,785 @ 6.89 bar

- Maximum flowrate 3785

- SAP number VMH3X3P

- Connection Flange

- Connection type PN16

- Size 3″/DN80

- Size 2 3″ Body

- Finish Flame red RAL3000

- Main material Stainless steel 316 | Flange: Stainless steel

- Style Manual – Handwheel

- Movement 2 Swivel – Vertical, Horizontal

- Maximum working pressure 17,2

- Nominal flowrate 3,785 @ 6.89 bar

- Maximum flowrate 3785

| SAP number | Connection | Connection type | Size | Size 2 | Finish | Main material | Style | Movement | Maximum working pressure | Nominal flowrate | Maximum flowrate |

|---|---|---|---|---|---|---|---|---|---|---|---|

| VMH3X3A | Flange |

ANSI |

3″/DN80 |

3″ Body |

Flame red RAL3000 |

Stainless steel 316 | Flange: Stainless steel |

Manual Handwheel |

2 Swivel Vertical, Horizontal |

17,2 |

3,785 @ 6.89 bar |

3785 |

| VMH3X4A | Flange |

ANSI |

4″/DN100 |

3″ Body |

Flame red RAL3000 |

Stainless steel 316 | Flange: Stainless steel |

Manual Handwheel |

2 Swivel Vertical, Horizontal |

17,2 |

3,785 @ 6.89 bar |

3785 |

| VMH3X4P | Flange |

PN16 |

4″/DN100 |

3″ Body |

Flame red RAL3000 |

Stainless steel 316 | Flange: Stainless steel |

Manual Handwheel |

2 Swivel Vertical, Horizontal |

17,2 |

3,785 @ 6.89 bar |

3785 |

| VMH3X3P | Flange |

PN16 |

3″/DN80 |

3″ Body |

Flame red RAL3000 |

Stainless steel 316 | Flange: Stainless steel |

Manual Handwheel |

2 Swivel Vertical, Horizontal |

17,2 |

3,785 @ 6.89 bar |

3785 |

Additional part numbers might be available. Please refer to the technical documentation or contact your local Viking sales office for more information.